Our company has long-standing experience in designing and installing automation systems. AMRs are another solution we offer to enhance efficiency in industrial material handling. We can design robots and modular components tailored to each customer's needs, as well as provide comprehensive automation system design and installation for industrial facilities.

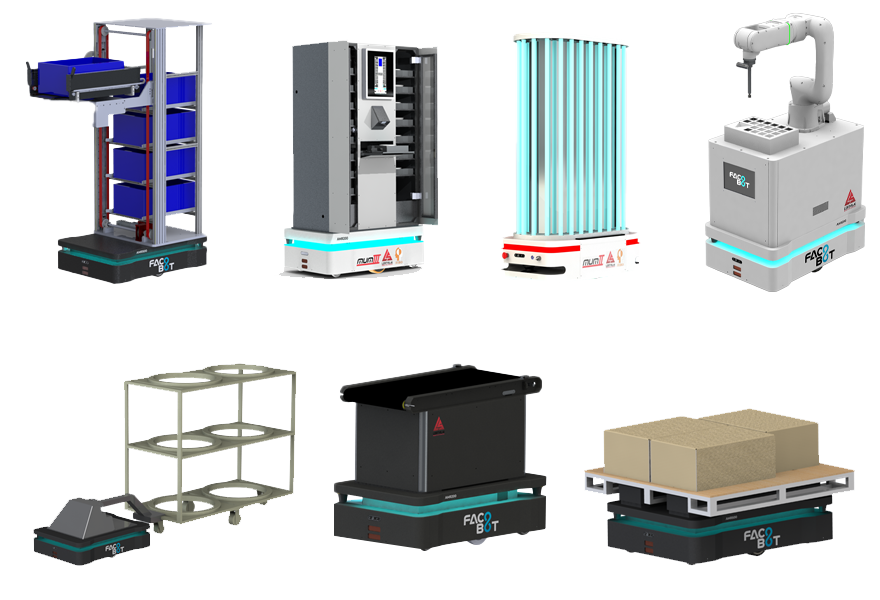

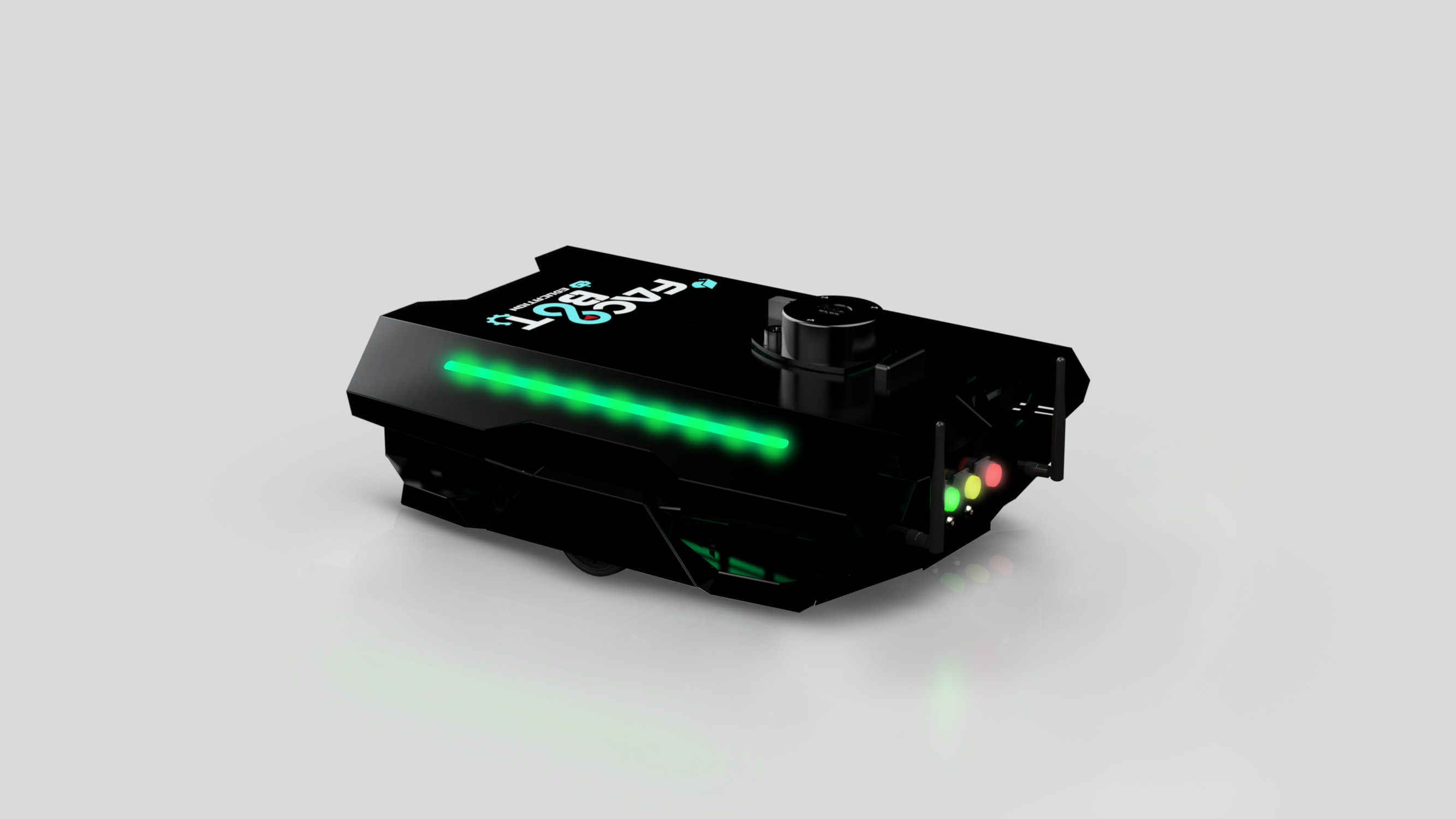

The Autonomous Mobile Robots (AMRs) under the FACoBOT brand of Lertvilai and Sons Co., Ltd. have been developed to support a wide range of indoor applications. These robots can be customized by replacing or upgrading the top modules to suit different types of operations.

The top modules (Modules) can be selected from existing designs for direct use, or tailored to meet the customer’s specific requirements. This flexibility allows AMRs to seamlessly adapt to diverse industrial needs.

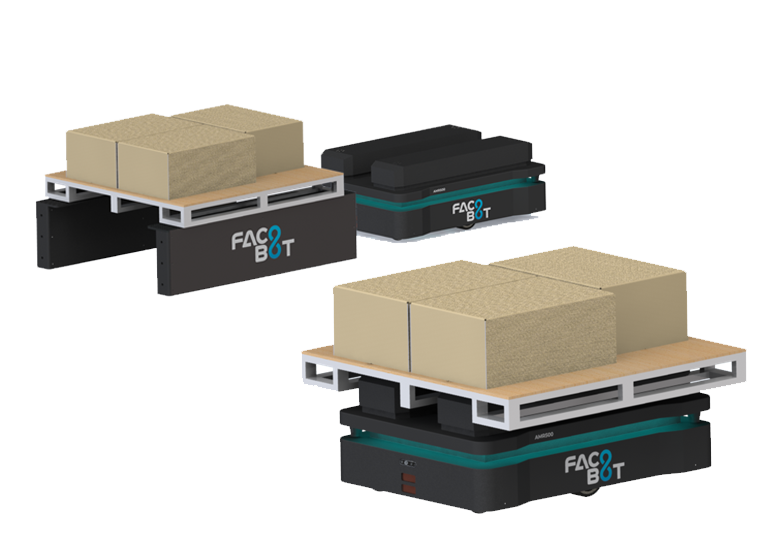

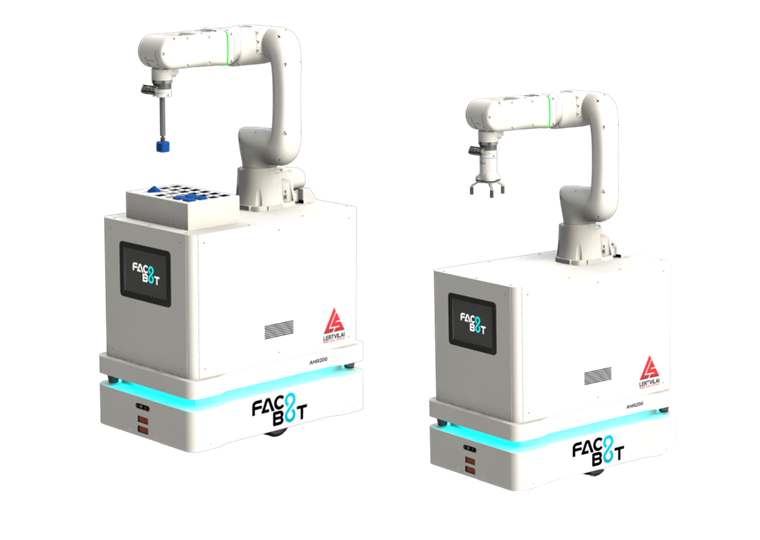

AMRs Robots under the FACoBOT brand come with a variety of sample modules for different types of work such as Picky Back Module, Cart Towing Module, Food/Medicine Dispensing Module, Conveyor Module, UV Disinfection Module, Pallet Lift Module, and Cobot Module.

We can provide guidance to help customers select the AMRs Robot that best matches their specific applications.

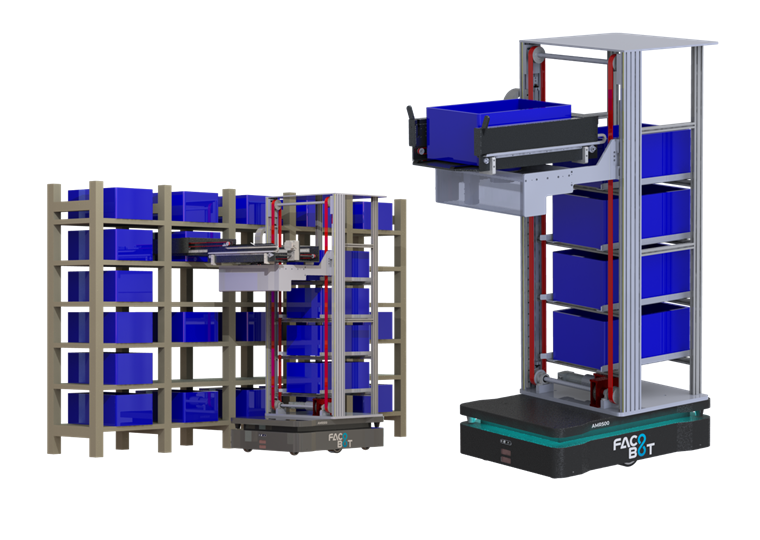

This is a module designed for transporting product boxes within a warehouse. It can move up to 6 boxes at the same time. The boxes used must be of the same size, with a maximum weight of 20 kilograms each, and their dimensions must comply with the specifications supported by the AMR Picky Back Module.

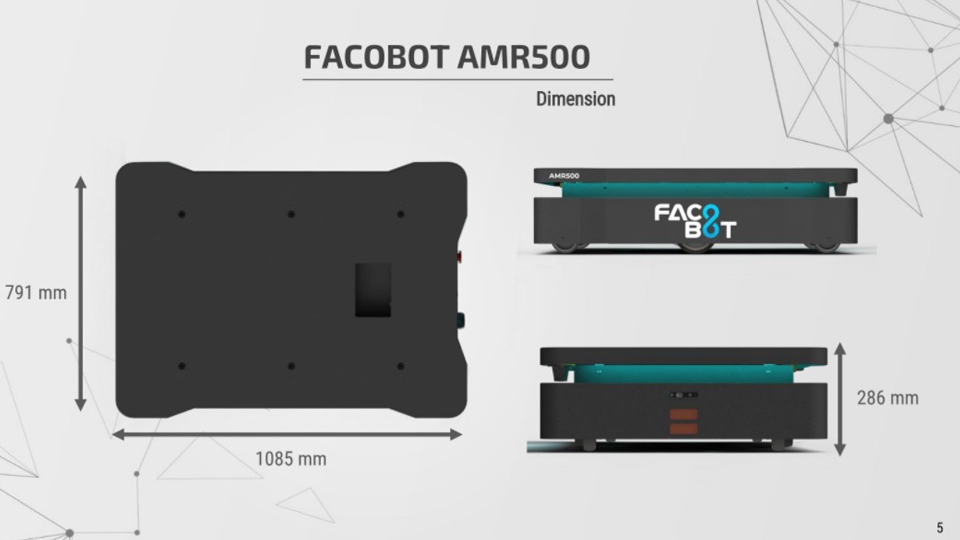

This module is designed for towing or transporting heavy loads between the warehouse and the production line. Users can set the travel route and pick-up/drop-off points. The module can tow up to 400 kilograms when used with the FACoBOT AMR200, and up to 750 kilograms when used with the FACoBOT AMR500.

This module is designed for delivering food and medicine within hospitals during the COVID-19 situation. It can hold up to 15 compartments (each compartment measuring 20×20×6 cm). A QR code system is used to verify patient identity, enhancing safety in food and medicine delivery. The food information and the robot’s operating status are displayed on the module’s LCD screen for convenient use by both patients and nursing staff.

This module is designed for delivering food and medicine within hospitals during the COVID-19 situation. It can hold up to 15 compartments (each compartment measuring 20×20×6 cm). A QR code system is used to verify patient identity, enhancing safety in food and medicine delivery. The food information and the robot’s operating status are displayed on the module’s LCD screen for convenient use by both patients and nursing staff.

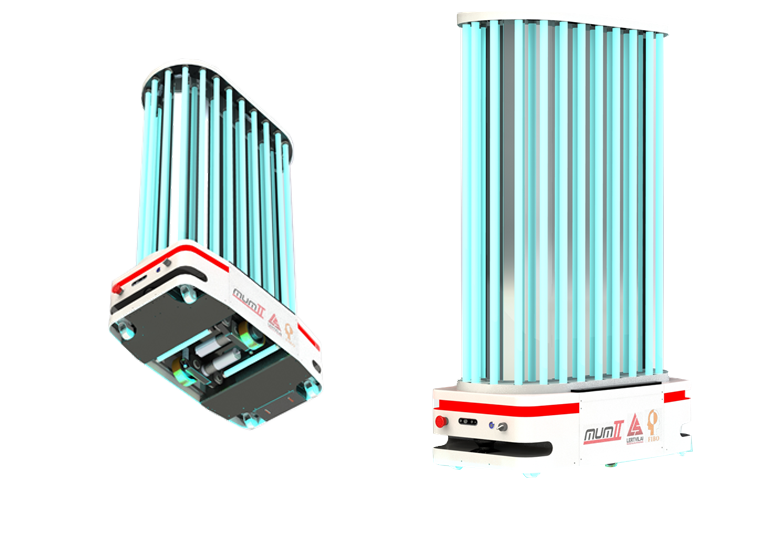

This module is designed for disinfection inside rooms or buildings. It emits UV-C light in all directions to eliminate pathogens, with an operating time of 4–5 hours. It comes equipped with software that calculates the robot’s travel path to maximize coverage and ensure thorough disinfection of the entire area.

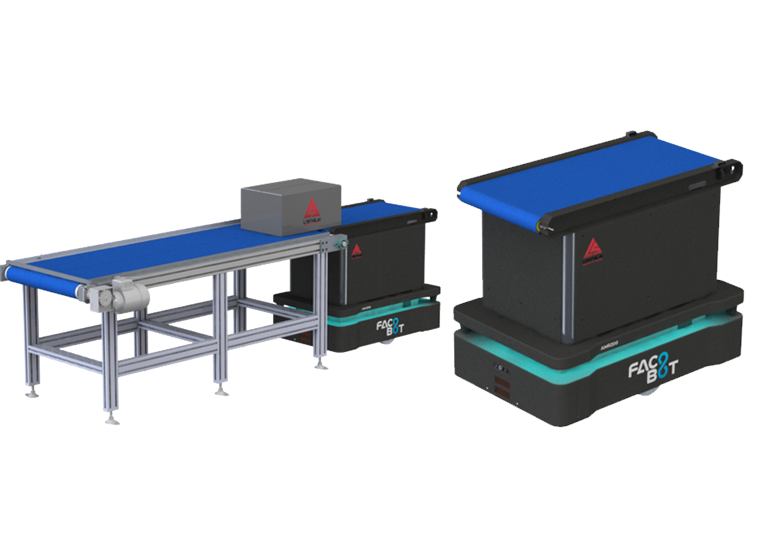

This module is used for transferring pallets between a pallet stand and a station. It is suitable for moving goods arranged on pallets within production stations or warehouses. The Pallet Lift Module can handle loads of up to 500 kilograms and is compatible with the FACoBOT AMR500.

This is a robotic arm module designed to safely work alongside humans. It is mounted on an AMR to handle objects that require high flexibility in gripping. The module is integrated with a 3D camera to accurately determine the position for precise and reliable object handling.

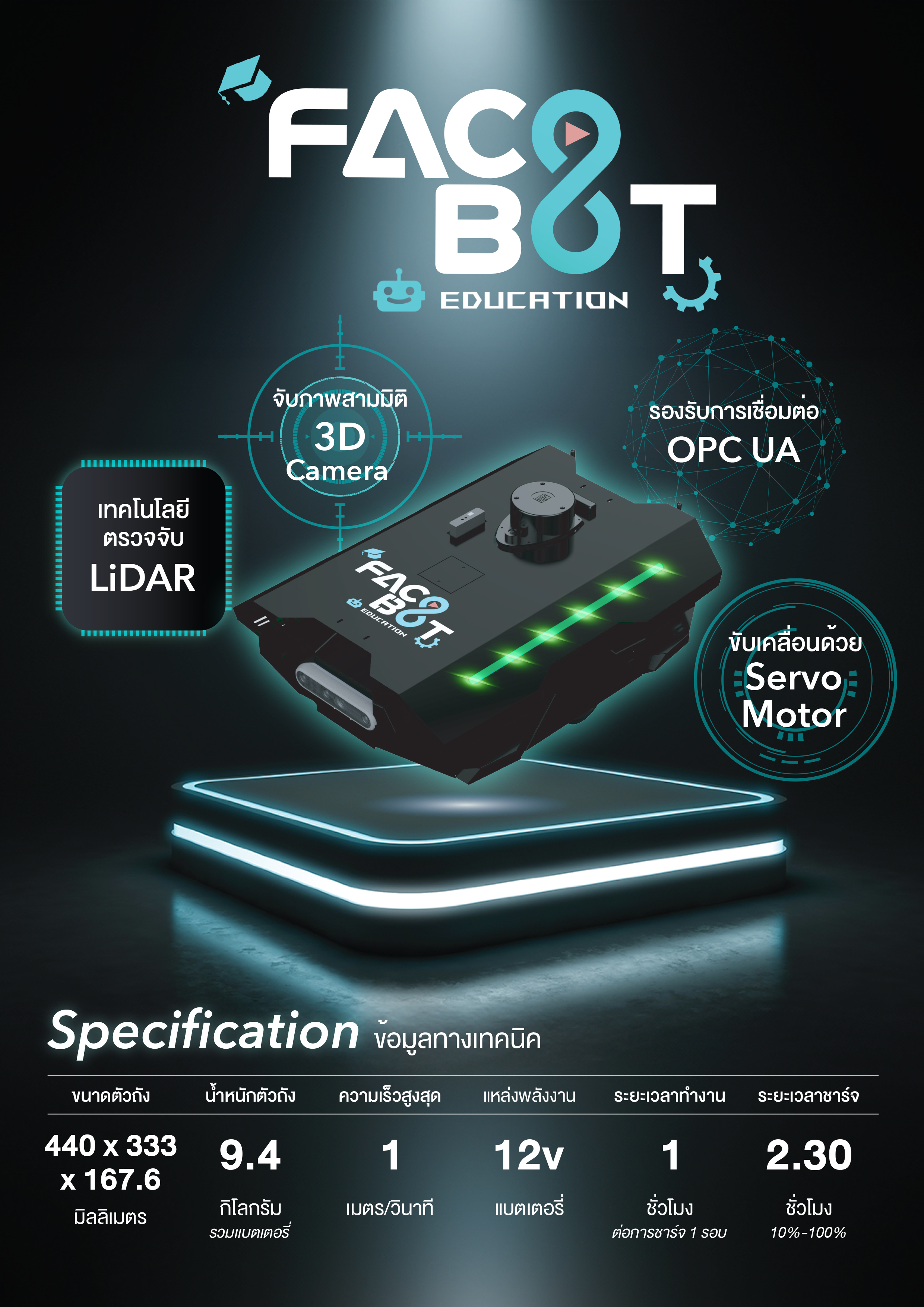

Our AMR Training Set and FACoBOT for Education are designed to bring real-world automation and robotics into the classroom. With modular learning, hands-on practice, and Industry 4.0 applications, learners gain practical skills for the future of smart manufacturing.

we have the facility for research and after-sales service. We make sure that your solution is truly the best one.